INTERMODAL TRANSPORT AS AN ATTRACTIVE

MODE OF TRANSPORT

Bartosz Guszczak*

* Institute of Logistics and Warehousing, Poznan, Estkowskiego 6, 61-755, Poland, Email: bartosz.guszczak@ilim.poznan.pl

Abstract This article shows intermodal transport as an effective mode of transport. In the article

are presented examples of best practices, i.e. successful projects regarding utilisation of rail transport, which includes showing methods of effective, economical and resource-efficient integration of rail transport with other logistics processes. The examples show that rail transport can be an added value for the companies and society.

Paper type: Research Paper Published online: 09 July 2014

Vol. 4, No. 3, pp. 209-219 ISSN 2083-4942 (Print) ISSN 2083-4950 (Online)

© 2014 Poznan University of Technology. All rights reserved. Keywords: supply chain, intermodal transport, rail transport

1. INTRODUCTION - INTERMODAL TRANSPORT –

AN EFFECTIVE METHOD OF GOODS HAULAGE

Intermodal transport belongs to complex transport processes in which cargo is transferred by means of transport utilised in different transport branches (Min-dur, 2002, p. 233). Additionally, cargo is transported within a single ITU (Inter-modal Transport Unit), e.g. a container, swap body, semi-trailer, etc., within the entire route using means of transport belonging to different transport branches. The means of transport used for transferring cargo may include:

• road vehicles, • rail vehicles,

• ships,

• river barges.

In Poland, all transport branches may be used for intermodal transport activities. However, in practice, inland shipping is hardly ever used for intermodal transport purposes. The most common solution combines sea transport with rail and road transport. The authors of this paper intend to focus on rail transport, for which new possibilities appear, resulting from the growing number of cargos transported in containers. Simultaneously, in recent years, rail transport has become more competitive and customer-oriented thanks to opening the market, intensifying competition and, as a result, increasing the variety of available offerings. Thus rail transport stands a considerable chance of dynamic development in the future in conjunction with the increase in the transport size and efficiency.

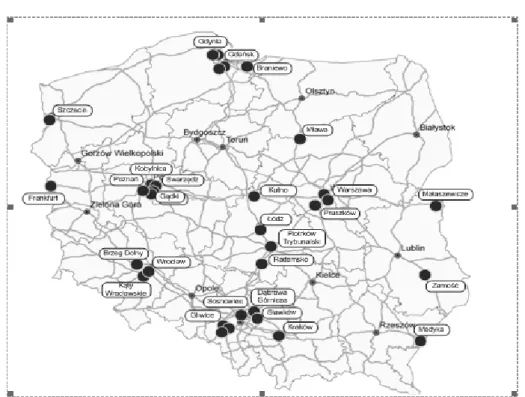

Properly developed line infrastructure (railways) and spot infrastructure (con-tainer terminals) constitute inseparable elements of intermodal transport. This must include railways ensuring highest technical parameters and a network of container terminals which facilitate reloading of an intermodal transport unit among means of transport used. During the last 7 years, the number of container terminals located in Poland has increased by over 60%. See the figure below for locations of 33 ex-isting container terminals which facilitate reloading intermodal transport units

In March 2011, the European Commission published the "White Paper" on transport. This document entitled „Roadmap to a Single European Transport Area – Towards a competitive and resource efficient transport system” has a strate-gic character. The White Paper presents the assessment of the transport policy as regards recent years and results of research as regards long-term challenges. It also makes it possible to identify the objectives to be achieved in the next 40 years (by 2050) and defines detailed framework conditions for activities in the area of the transport policy in the next 10 years. By 2050, the White Paper recom-mends that even over 50% of all long-distance vehicular transport be replaced by other means of transport, in particular rail transport. In comparison with 2005. One of the methods aimed at achieving the above-mentioned ambitious goals as regards increasing the share of rail transport in the overall transport activities

is the presentation of the selected best practices detailing successful implementa-tions of pro-ecological transport projects. Among other, the above is achieved by the FLAVIA project.

Fig. 1 Network of existing container terminals in Poland (Hajdul, 2012, p. 95)

Any action to promote intermodal transport make that the number of transported TEU (Twenty-foot Equivalent Unit) is much higher in 2012 - compared to 2011. In 2012, it was transported by 31.12% more TEUs than in 2011. Details are shown in table 1.

Table 1 TEU transported in intermodal transport (www.utk.gov.pl)

Year I quarter II quarter III

quarter IV quarter Total 2012 254976 264317 255742 271947 1046982 2011 164763 182247 208876 242598 798484 2010 132412 152255 152588 146368 583623 change 2012/2011 54,75% 45,03% 22,44% 12,10% 31,12%

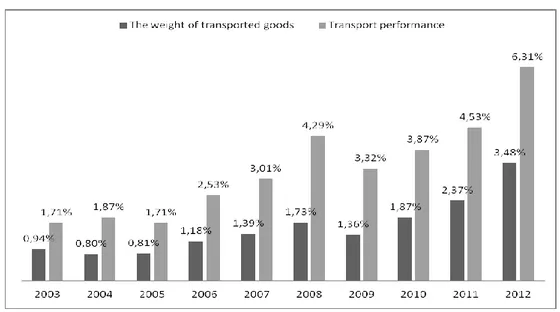

It can be observed that increased the share of intermodal transport in the railway market in the years 2003-2012 (Fig. 2). It is crucial to increase of intermodal transport remained within the next year. It brings benefits for companies (especial-ly what is essential for each market player, the financial benefits) as well as for society (reduction of CO2, less congestion, etc.). The promotion of intermodal transport is contributed to a variety of projects, even if the FLAVIA project which is reported in detail below.

Fig. 2 The share of intermodal transport in the railway market in the years 2003-2012

(www.utk.gov.pl; Funkcjonowanie rynku transport kolejowego w 2011 roku, wrzesień 2012, Urząd Transportu Kolejowego)

2. INTERMODAL TRANSPORT – CASE STUDY

2.1. FLAVIA project

The term FLAVIA stands for Freight and Logistics Advancement in Cen-tral/South-East Europe – Validation of trade and transport processes, Implementa-tion of improvement acImplementa-tions, ApplicaImplementa-tion of co-coordinated structures. The FLA-VIA European Union project contributes to the improvement of logistics in Cen-tral and South-Eastern Europe. Thanks to validating transport and commercial struc-tures/processes, the project presents assumptions for improving and consolidating co-operation structures. The project is implemented by 14 partners from 7 European coun-tries, i.e. Poland, Czech Republic, Slovakia, Hungary, Romania, Austria and Germany.

An important objective of FLAVIA is to present through brochures examples of best practices, i.e. successful projects regarding utilisation of rail transport, which includes showing methods of effective, economical and resource-efficient integra-tion of rail transport with other logistics processes. The project collects success stories of enterprises which, during the last few years, have shifted their transport processes from road to rail transport. Table 2 presents the companies that have been identified within the FLAVIA project.

Table 2 Companies identified in the FLAVIA project (Own study based on Flavia Project

data)

No. Companies Coments

1. Blum Polska Sp. z o.o.

2. Can-Pack S.A.

3. Castorama Polska Sp. z o.o.

4. Pfeifer & Langen S.A.

5. Jysk Sp. z o.o.

6. Knauf Trans Polska Sp. z o.o.

7. Lafarge Cement S.A.

8. Baltic Rail AS Rail World Group

9. Volkswagen Group Polska In the FLAVIA brochure company is

presented under the name of Skoda Auto Poland S.A. However, in June 2012, the Skoda Auto Poland ceased to exist, while the Skoda brand begins to function within the framework of the Volkswagen Group Poland Sp. z o.o.

10. ThyssenKrupp Metallurgical Products GmbH

See below for two examples of such best practices (Can-Pack S.A and Pfeifer & Langen S.A.). It should be added here that data status of the following examples is dated on May 2012.

2.2. Intermodal transport – Can Pack S.A. case study

Can-Pack S.A. has production facilities all over the world and is one of the leading players on the global market for metal packaging, e.g.:

• two-piece aluminium beverage cans with easy-open aluminium ends for beer and soft drinks,

• round steel food cans and shaped cans for vegetable and meat products,

• steel bottle closures (crown corks) for use with beverage and mineral-water bottles made of glass,

• easy-open steel ends for use with steel cans for meat and fruit/vegetable products.

At the onset, the metal beverage cans were transported from the plant located in Brzesko, between Cracow and Tarnów, to the Gdynia port by means of road transport. The cans loaded to containers on the Can-Pack S.A. premises in Brzesko travelled approx. 700 km throughout the whole country on Polish roads to be deliv-ered to the Gdynia port, from which they were forwarded by ships. However, road transport became less and less effective, i.e. as a result of increasing difficulties in obtaining access to lorries adjusted to transporting cargo containers. Additional-ly, the prices for road carriers' services have increased rapidly during the last few years. Due to the above, an attempt to deliver cargos by means of rail transport has been made. In practice, this solution appeared to be a good move and, as a result, it has been successfully implemented since 1 March 2011 when the first train car-rying containers loaded with metal beverage cans was sent to the Gdynia port.

Fig. 3 Loading cans to containers (Can-Pack S.A.)

The replacement of road transport with rail transport has influenced the transfor-mation of product distribution organisation in Can-Pack S.A. Presently, the cargo is loaded to containers already located on rail cars directly at the siding situated

with-in Can-Pack S.A. premises. This elimwith-inates the necessity to transport contawith-iners by road to a container terminal, which results in considerable savings, both in terms of money and time. Next, the containers are transported by rail from Brzesko directly to the Gdynia port and shipped through the Baltic Sea to a Finnish ordering party.

It must be added here that the fact of shifting from road transport to rail tran-sport has significantly contributed to streamlining the warehouse operation as the process of providing rail cars for loading is planned in such a manner that it does not interfere with the process of loading lorries. This solution enables the company to optimally and effectively utilise the resources stored in distribution warehouses.

Another important reason for shifting the goods distribution from road transport to rail transport is environmental protection treated as a priority by Can-Pack S.A.. The evidence for this is the fact that the company maintained the costly railway siding within the plant premises even though rail transport was used to a limited extent. Each week, Can-Pack S.A. ships approx. 30 containers by means of 45’ rail transport from Brzesko to Gdynia. However, in this case providing the weight of shipped goods in tonnes is not a reliable method as the transported goods (alu-minium cans) are very light. Thus it must be mentioned that a 45’ container ships approx. 3 tonnes of cargo.

It is also worth highlighting that Can-Pack S.A. has not borne any costs con-nected with shifting from road transport to rail transport. The reason for this is obvious, i.e. the company uses its own rail siding located within its premises.

With hindsight, company's representatives consider the above-mentioned deci-sion as a favourable one, which results from several reasons:

• the problem with the temporary shortages of lorries adjusted to transpor-ting containers has been solved,

• the operation of the warehouse has been considerably streamlined,

•

thanks to shifting the modes of transport, the company achieved savings estimated on the level of 15%.2.3. Intermodal transport – Pfeifer & Langen Poland S.A. case study

The beginning of the German company Pfeifer & Langen in Poland is dated on 1995, which, together with the Treasury created the company ”Cukrownia Środa Sp. z o.o.” (in Środa Wielkopolska). Its shareholders were employees of sugar factories, working with its growers, the Treasury and Pfeifer & Langen (took the 47% of shares).As a result of further investments, the German partner acquired more sugar fac-tories in Poland and the subsequent restructuring and mergers led to the creation of two independent entities: Pfeifer & Langen Poland S.A. and Pfeifer & Langen Marketing Sp. z o.o.

25th of November 2009, is the day of the next major investment of companies Pfeifer & Langen Poland S.A., which acquired a 100% share in the capital of

Brit-ish Sugar Overseas Poland Sp. z o.o. Today it is the Pfeifer & Langen Holding Sp. z o.o. – The majority shareholder in the BSO Poland S.A., whose current name is: Pfeifer & Langen Glinojeck SA

Table 3 Characteristics of Pfeifer & Langen Polska S.A. (Own study based on data

obtained from the Pfeifer & Langen Poland S.A.)

Transported goods Sugar

Number of transported goods by rail 80 000 tonnes of sugar in containers Motivation to transported foods by rail Financial, organizational

Rail route From factories in Gostyń, Miejska

Górka, Środa Wielkopolska and Glinojeck to the ports in Gdynia or

Gdańsk

Rail route distance Varied, depending on the sugar factory (from 270 to 420 km)

Both companies - Pfeifer & Langen Poland S.A. and Pfeifer & Langen Glino-jeck S.A. - are production companies and include factories operating in Gostyń, Miejska Górka, Środa Wielkopolska and Glinojeck and plant out of production, which have some warehousing functions: Góra Śląska, Głogów and Witaszyce. However, Pfeifer & Langen Marketing is a distribution company, which sells sugar to individual customers and industry (under the brand name DIAMANT).

Fig. 4 Visualization of route between the sugar factories and port of Gdynia (Flavia project

Company Pfeifer & Langen continuously exploited and used rail to distribute their products to foreign customers. The organization of distribution of goods from the factories belonging to Pfeifer & Langen is as follows: loading goods into con-tainers (that are already on the railway wagon) takes place directly on the sidings which are located in areas of sugar factories in Gostyń, Miejska Górka, and Glino-jeck. This eliminates the need to move containers from the rail platforms in another location, saving time and money. The exception is sugar factory from Środa Wiel-kopolska, which due to a considerable distance of finished goods warehouse from siding, logistical aspects and costs, there is rented a crane that removes the contain-er from the wagon, and aftcontain-er loading of the sugar, the containcontain-er is laid back on the wagon. Next containers are transported by rail to the port of Gdynia or Gdansk, where the ship sail to contractors (including Israel, Syria and Lebanon).

Pfeifer & Langen company transports annually 80 000 tonnes of sugar in con-tainers. Goods are distributed in containers of 20 '. In one container is up to 24 tons of goods, that is - otherwise counting - 480 bags of sugar, each weighing 50 kg. There are used larger package, the so-called “big bags”, then each of them weighs 1000 kg, but due to their size is transported up to 20 big bags in one container.

Fig. 5 Container on the train platform in one of the sugar factory belonging to Pfeifer

& Langen Poland S.A. (Pfeifer & Langen Polska S.A.)

It should be emphasized that the company Pfeifer & Langen, does not incur any additional costs associated with the supply of goods by rail. This is due to the fact that the company uses its own railway sidings, at the site of their sugar factories.

In retrospect, the representatives of Pfeifer & Langen consider very positive de-cision to implement the distribution of its products by rail. The company, using rail, gaining significant savings compared to road transport. Representatives of the company estimate that the distribution of sugar by rail is about 20% cheaper compared to road transport. Another very important issue is the organizational

matters. Annually, the company carries about 80 000 tonnes of sugar in containers. With such a huge amount of cargo it is easy to imagine that there would be chaos in the organization of the warehouse operation, if the distribution was carried out by road. In practice, this would mean the appearance at the same time a large num-ber of trucks on the factory grounds and its areas, that could paralyze local traffic and - consequently - to meet with opposition from local communities. In the case of rail transport problem that could be avoided.

3. CONCLUSION

The European Commission stated in its current "White Paper" as follows: "Railway is sometimes seen, particularly as far as freight transport is concerned, as an unattractive means of transport. However, certain examples of some compa-nies have shown that railway can offer high quality transport services". In fact, the rail freight transport has undergone a large transformation in recent years. A growing number of forwarders have discovered rail transport as an economically viable and environmentally friendly alternative to road transport for the movement of cargoes. Rail transport is used for whole routes of the cargo carriage its frag-ments within the framework of a multimodal transport chain.

The most important benefits that the companies achieved, include:

• reduction of transport costs - reducing costs, particularly the cost of transport is essential to the functioning of any business or commercial production. Transport costs in the logistics cost structure is the most important element, even exceeding the cost of maintaining inventory, order processing, warehousing, and warehouse operations (Żak, 2009, p. 142),

• organizational issues - to facilitate work in the warehouse,

• reliability of rail transport and more independence from transport problems on roads (e.g. congestion),

• better transport chain planning and integration with company's logistics processes.

The provided examples show that rail transport can be an added value for the companies and society because rail transport offers significant advantages as regards the climate and environment in relation to road transport, e.g. higher energy efficiency and lower CO2 emissions in comparison to road transport.

REFERENCES

Biała Księga, Plan utrzworzenia jednolitego europejskiego obszaru transportu – dążenie do osiągnięcia konkurencyjnego i zasobooszczędnego systemu transportu.

Christopher M., (2000), Logistyka i zarządzanie łańcuchem dostaw, Polskie Centrum Dora-dztwa Logistycznego.

Coyle J., Bardi E. & John Langley Jr. C., (2002), Zarządzanie logistyczne, PWE, Warszawa. Długosz J., (2009), Systemy transportowe, transport intermodalny, Logistyka, ILiM, Poznań. Fechner I., (2007), Zarządzanie łańcuchem dostaw, WSL, Poznań.

Funkcjonowanie rynku transportu kolejowego w 2011 roku, (wrzesień 2012), Urząd Tran-sportu Kolejowego, płyta CD.

Hajdul. M., (2012), Transport intermodalny, Logistyka w Polsce, raport 2011, Fechner I., Szyszka G. (eds.), ILiM, Poznań.

Kwaśniowski S. Nowakowski T. & Zając M., (2008), Transport intermodalny w sieciach logistycznych, Oficyna Wydawnicza Politechniki Wrocławskiej, Wrocław.

Mindur L., & Krzyżaniak S. (eds.), (2011), Tworzenie warunków funkcjonowania i rozwoju intermodalnej sieci logistycznej w Polsce. Aspekty metodyczne, ILiM, Poznań.

Mindur L. (ed.), (2002), Współczesne technologie transportowe, Politechnika Radomska, Warszawa.

Urząd Transportu Kolejowego, Analizy i monitoring rynku, biuletyn, raporty i aktualności statystyczne, www.utk.gov.pl. Accessed: 11.07.2013.

Żak J., (2009), „Podstawowe obszary działań logistycznych”, Transport, D. Kisperska-Moroń, S. Krzyżaniak (eds.), Logistyka, ILiM, Poznań.

BIOGRAPHICAL NOTES

Bartosz Guszczak is graduated Faculty of Computing Science and Management

on Poznan University of Technology. Currently he pursues a PhD dissertation on the concept of knowledge transfer in the supply chain. He works in Expertise Department at Institute of Logistics and Warehousing. At ILiM he is involved in research project, EU project and commercial projects as well. His research interests are logistics management, supply chain, knowledge transfer. Author of many publications.