DATABASE OF MULTI-VARIANT MACHINING

PROCESS PLAN

Łukasz Gola*

* Institute of Production Engineering and Automation, Cracow University of Technology, Kraków, 31-864, Polska, E-mail: lugola@gmail.com

Abstract This paper presents database of multi-variant machining process plan. This database is a part of CAPP (Computer Aided Process Planning) – prototype system, which was built on the basis of algorithm generating multi-variant process plan. Database was implemented to Microsoft Access 2010.

Paper type: Research Paper Published online: 09 July 2014 Vol. 4, No. 3, pp. 201-207 ISSN 2083-4942 (Print) ISSN 2083-4950 (Online)

© 2014 Poznan University of Technology. All rights reserved.

1. INTRODUCTION

Computer aided process planning systems are built with adaptation three basic methodical approaches: variant method, semi-generative method, generative method. Generative method has the most possibilities among remaining methods, particularly if it depends us on considerable to raise the automation of machining process plans. Generative method is more difficult in comparison with variant method, because generative method require to create more formal models which describes different working and objects on process planning. In Institute of Production Engineering research have brought to make algorithm generation machining process plan so far (Samek 1996), (Duda, 2000). The main feature of this algorithm is based on possibility choice by technologist partial solutions from admissible set on given stage.

But progress enabling realization of concurrent product development is defined requirements for computer aided process planning systems:

• The ability to projection machining process plans for wide set of typical parts of machines, the elements of component products,

• The ability to projection machining process plans with regard the fit ma-nufacturing capabilities,

• The ability to generation of variants machining process plans with different degree of circumstantiality.

Above mentioned features were reached building generative skeletal system CAPP, which it be characterizes:

• The possibility of record, modification and manufacturing knowledge, • The possibility of record technological profiles of manufacturing system

oriented on profile realized in enterprise of productive processes, the possibility generation admissible solutions which are realized on manu-facturing stations.

2. ALGORITHM OF GENERATION MULTI-VARIANT

PROCESS PLAN

The effect of previous work carried out in Institute of Production Engineering was to develop algorithm of generation multi-variant process plan (Gola, 2012). Based on the basic structure of the process plan PT (1), defined places where we can create variants of process plan (Duda, 2008), (Gola 2012). The process plan PT has a hierarchical structure. Generally process plan consist from operations, fixtur-ings, positions and cuts but must be preserve principle: one operations is set of more fixturings, positons and cuts, one fixturing is set of more positions and cuts and one positon is set of more cuts.

PT = [OP-operation [US-set-up [PZ-position [ZB-cut]]]] (1) Places (where we can create variants of process plan) were the basis for the de-velopment algorithm of generation multi-variant process plan (Fig 1).

Creation object PT

Operating procedures

Generating operation

Generating set-up

Possible choice of machine and equipment tools?

next set-up ?

Generating positions

CAD system

Specify a list of transformation technological features, the set of

intermediate states ListPTTR

Creation object OP Creation object VS Download operation procedure Operation from BDWPT ? START

Chracteristic of semi-finished part and intermediate states No END Database of workpices Database of workpices TAK Yes Yes Database of technological capability manufacturing system oriented for machines kinematics Database of multi-variant process plans (BDWPT) First variant of operation VOP next operation ? next structure variant ? No No

Multi-variant process plan No

Generating cuts

Creation object VOP

Yes next variant operation ? ListTrOp_1 ListTrOp_2 On ListTrOp2 the same transformations for ListTrOp_1? VOP incompa- tible VOP compatible NIE Yes No Yes No No Yes Yes

The algorithm is carried out at different levels, including: generating operations, generating set-ups, generating positions, generating cuts. The algorithm can gener-ate acceptable variants (possibilities of movement of individual machine compo-nents). Calculation procedures on this algorithm are based on a simple kinematics task and reverse kinematics task. Necessary data to generate acceptable variants are stored on Database of technological capability manufacturing system oriented

for machines kinematics.

3. DATABASE OF MULTI-VARIANT MACHINING

PROCESS PLAN

Generated machining process plan is saved to database of multi-variant machining process plan (BDWPT). Need to write multi-variat structures of machining process plan and possibility to use such a database by PPC (Production Palning Control), resulted in the design and construction of such a database from the base. The high level of integration in such complex systems, which are for example CAPP systems, achieved by using a common data model PPR (Product, Process, Resourses).

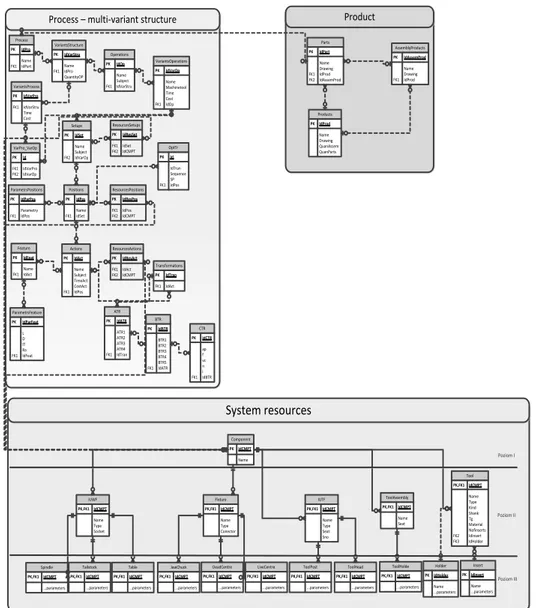

Process PK IdPro Name FK1 IdPart VariantsOperations PK IdVarOp Name Machinetool Time Cost FK1 IdOp Operations PK IdOp Name Subject FK1 IdVarStru Setups PK IdSet Name Subject FK2 IdVarOp ResourcesSetups PK IdResSet FK1 IdSet FK2 IdCMPT Positions PK IdPos Name FK1 IdSet ParametrsPositions PK IdParPos Parametry FK1 IdPos ResourcesPositions PK IdResPos FK1 IdPos FK2 IdCMPT Actions PK IdAct Name Subject TimeAct CostAct FK1 IdPos Feature PK IdFeat Name FK1 IdAct ParametrsFeature PK IdParFeat L D IT Ra FK1 IdFeat Transformations PK IdTran FK1 IdAct ATR PK IdATR ATR1 ATR2 ATR3 ATR4 FK1 IdTran BTR PK IdBTR BTR1 BTR2 BTR3 BTR4 BTR5 FK1 IdATR CTR PK IdCTR ap f vc n i FK1 IdBTR VariantsStructure PK IdVarStru Name FK1 IdPro QuantityOP ResourcesActions PK IdResAct FK1 IdAct FK2 IdCMPT Products PK IdProd Name Drawing QuanAssem QuanParts AssemblyProducts PK IdAssemProd Name Drawing FK1 IdProd Parts PK IdPart Name Drawing FK1 IdProd FK2 IdAssemProd

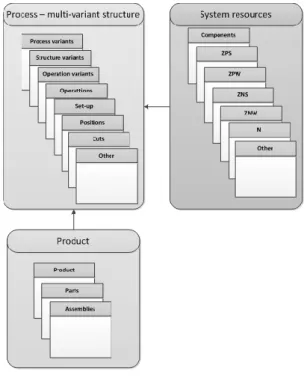

Process – multi-variant structure Product

IUWF PK,FK1 IdCMPT Name Type Socket Spindle PK,FK1 IdCMPT ...parameters Tailstock PK,FK1 IdCMPT ...parameters Table PK,FK1 IdCMPT ...parameters Fixture PK,FK1 IdCMPT Name Type Conector JawChuck PK,FK1 IdCMPT ...parameters DeadCentre PK,FK1 IdCMPT ...parameters LiveCentre PK,FK1 IdCMPT ...parameters IUTF PK,FK1 IdCMPT Name Type Seat Sno ToolPost PK,FK1 IdCMPT ...parameters ToolHead PK,FK1 IdCMPT ...parameters ToolAssembly PK,FK1 IdCMPT Name Seat ToolHolde PK,FK1 IdCMPT ...parameters Tool PK,FK1 IdCMPT Name Type Kind Shank Tg Material Nofinserts FK2 IdInsert FK3 IdHolder Holder PK IdHolder Name ...parameters Insert PK IdInsert Name ...parameters System resources Component PK IdCMPT Name Poziom I Poziom II Poziom III VariantsProcess PK IdVarPro FK1 IdVarStru Time Cost VarPro_VarOp PK Id FK1 IdVarPro FK2 IdVarOp OptTr PK Id IdTran Sequence SP FK1 IdPos

Fig. 3 BDWPTO - logical model

This model enables data exchange between modules used in the design process. Therefore, the database is divided into three parts (areas):

• Process – multi-variant structure, • System resources,

• Product.

To stored informations about the machining process plan, it is necessary to rep-licate the structure process. This information is stored in the part

the structure of the process variant, variant operations, operations, set-ups, posi-tions, cuts, transformaposi-tions, technological features,.... On the part System resources stored informations about resources system (machines, tools, ...). On the part

Prod-uct stored informations about prodProd-ucts for which the manufacturing process is

de-signed. The following diagram shows the logical data model of BDWPT (Fig 3). 3.1. Implementation

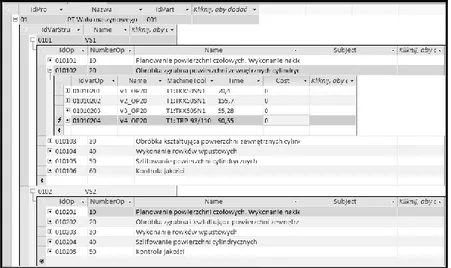

The database has been implemented to MS Access 2010 (Fig. ) In order to validate the designed and built database, stored in it multi-variant machining process plan of machine shaft (18 variants).

Fig. 4 BDWPT - example of the multi-variant machining process plan

This was followed by a test database search. Formulated for this purpose severa SQL queries. Below is a sample query and the result has been attained:

Question 1

Show the process variants VPT that time TP is less than 200 [min] SELECT VariantsProcess.[IdVarPro], VariantsProcess.[Time] FROM VariantsProcess

WHERE (((VariantsProcess.[Time])<"200")); Answer:

3. CONCLUSION

Presented in the article database allows to record information about the multi-variant machining process plan. Clearly designed form of database, cause easy and intuitive data entry. This database is an essential element of CAPP which generates multi-variant process plan. Generated variants of process plan next can be used in the construction of production schedules.

REFERENCES

Duda J., Habel J. & Gola Ł, (2008), Koncepcja generowania wielowariantowych procesów technologicznych obróbki, New ways in manufacturing engineering´2008, Prešov, Slovak Republic, pp. 19–21.

Duda J., (2000), Opracowanie założeń systemu projektującego procesy technologiczne próbki w warunkach inżynierii równoczesnej z wykorzystaniem sztucznej inteli-gencji, Projekt badawczy nr 7T07D02812 finansowany przez KBN.

Gola Ł., (2012), Wielowariantowe generowanie struktur procesów technologicznych obróbki w systemach CAPP, Praca doktorska, Kraków.

Samek A., (1996), Zasady budowy systemu projektowania i doboru oprzyrządowania przedmiotowego z wykorzystaniem metod hybrydowych, Projekt Badawczy PB-657/T07/95/08 praca wyk. kier. prof. dr hab. inż. A.Samka. ITMiAP Poli-technika Krakowska, Kraków.

BIOGRAPHICAL NOTES

Łukasz Gola is currently a researcher and teacher on Institute of Production Engineering and Automation at the Cracow University of Technology. Her research interests include machining process plans, assembly process plans, CAPP systems, production scheduling and process optimization, methods of working time measuring and standardization of work time.